Beijing New Airport Terminal Area Project

Beijing, China

-

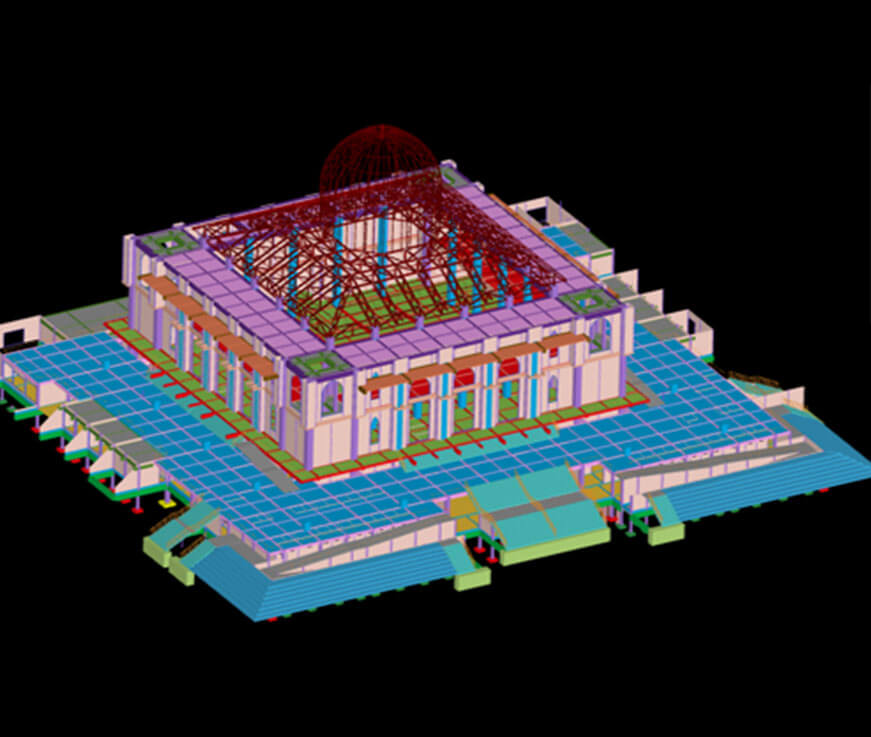

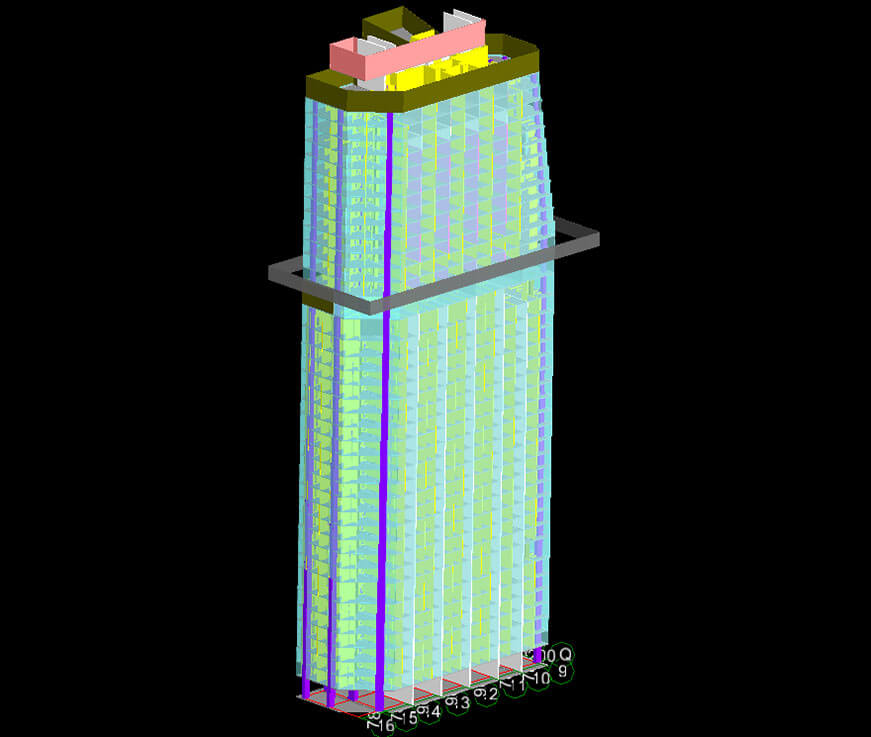

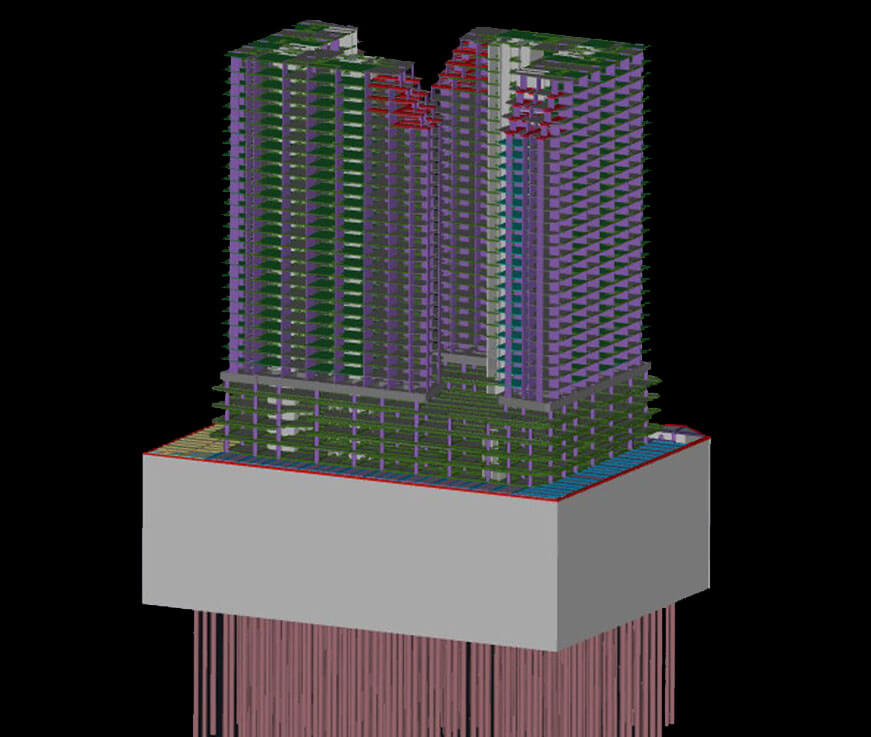

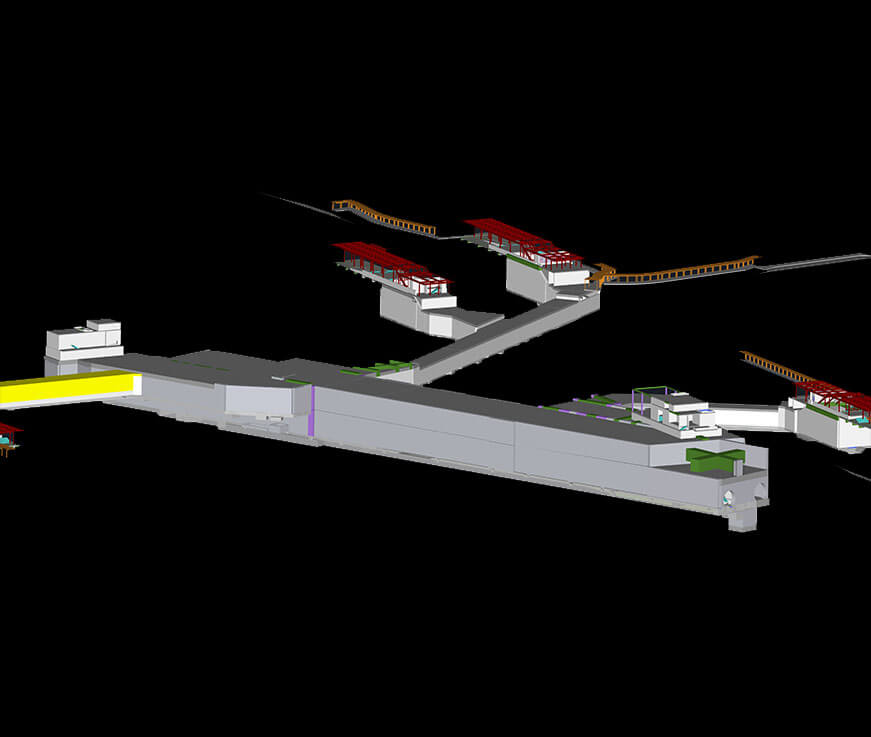

Project Type & Description: A large-scale building complex with cast-in-place reinforced concrete frame structure, having the terminal building as its center and being composed of several supporting projects.

-

Gross Land Area: 1,430,000 ㎡

-

Glodon Products Involved: Project Cost Estimating+ BIM application, Gsite

An Extraordinary International Airport - Innovative Digital Building

As a key project at the national level, this project is a large-scale building complex composed of several supporting projects and it is also the largest single building featuring vibration isolation in the world. Its structure is super-long and large with varied shapes. With multiple participants involved, the project requires better construction technology and management.

Key Insights

i.BIM technology is efficient to perform modeling, layout scheme simulating, and scheme comparing for steel plank road for temporary transportation in the super-large and ultra-long structuring work. In this way, it can eliminate technical hardships from structural design in a fast and efficient way, and to use and position selection of such steel plank road.

ii. BIM technology also works well to perform modeling for isolation bearing and simulating for nearly 20 construction procedures. It can inspect the scientificity and rationality of the procedure setting so as to shorten the time length of technical disclosure and to ensure the uniformity and work quality of the entire construction procedure in a more visual manner.

iii. Work quantities marked for the secondary structural openings will be reduced by more than 80% by performing detailed design of the M&E system. And construction efficiency of the M&E work will be promoted by 10 to 15% through the reasonable arrangement of cables and wires.

iv. BIM 5D management platform can promote the efficiency of management data transfer by 15 to 20% and decision making by more than 10% and reduce the time of materials extraction by 15 to 20%.

Solutions

i.5D Model

It can perform simulation and analysis for geological conditions through the surface model, earthwork model, slope model, and pile foundation model apart from earthwork excavation difference calculation, animation production of visualized presentation, and lean management of 8,275 piles.

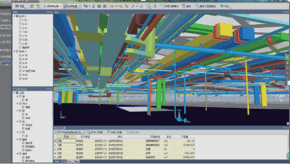

ii. Automatically Generate Structural Openings & Markings

It can achieve the automatic generation of secondary structural openings and markings, which can greatly reduce marking workload, avoid marking errors of manually caused, and greatly improve the accuracy and uniformity of marking work.

It can achieve the automatic generation of secondary structural openings and markings, which can greatly reduce marking workload, avoid marking errors of manually caused, and greatly improve the accuracy and uniformity of marking work.

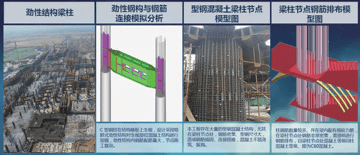

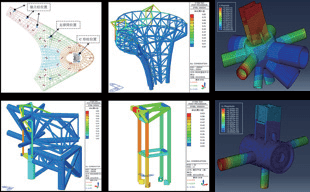

iii. Process Simulation of Rigid Steel Structure

Before the official commencement of construction, staff responsible for detailed design will perform lofting simulation for all rigid steel structures and reinforcements via BIM technology and complete the opening of steel rib and welding of the reinforcement connector in steel structure processing. Through close liaison with structural designers, the project team produced a complete detailed design scheme to guide on-site construction.

Before the official commencement of construction, staff responsible for detailed design will perform lofting simulation for all rigid steel structures and reinforcements via BIM technology and complete the opening of steel rib and welding of the reinforcement connector in steel structure processing. Through close liaison with structural designers, the project team produced a complete detailed design scheme to guide on-site construction.

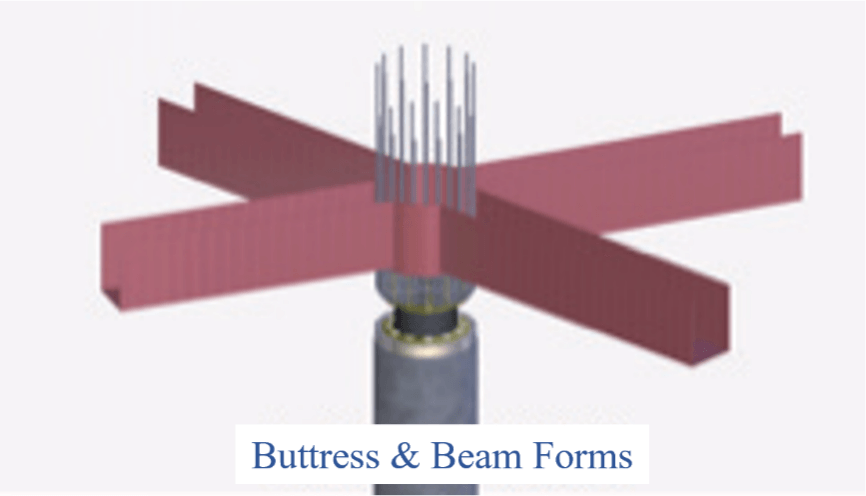

iv. Process Simulation of Isolation Bearing

It refers to construction simulation of nearly 20 procedures of the isolation bearing which can improve the accuracy and uniformity of technical disclosure, contribute to a better knowledge of construction milestones for construction staff on-site and shorten the time length for procedure disclosure.

The project is the largest single building featuring seismic isolation in the world, with a total of 1,124 sets of isolation rubber bearings being used. It utilized the super-large diameter isolation bearings in a super-large area and on a super-large scale for the first time both at home and abroad.

It refers to construction simulation of nearly 20 procedures of the isolation bearing which can improve the accuracy and uniformity of technical disclosure, contribute to a better knowledge of construction milestones for construction staff on-site and shorten the time length for procedure disclosure.

The project is the largest single building featuring seismic isolation in the world, with a total of 1,124 sets of isolation rubber bearings being used. It utilized the super-large diameter isolation bearings in a super-large area and on a super-large scale for the first time both at home and abroad.

v. Simulation of Construction Scheme of a Temporary Steel Plank Road

For the first time, the project team applied a steel plank road to the construction work featuring a super-large plane so as to resolve the problem of insufficient hoisting times of the tower crane in the middle part of the deep groove area. Regarding scheming making and designing of the steel plank road, BIM technology will be used to perform scheme comparison such as detailed BIM simulation, checking and calculating of root form, support system, component selection, and stress imposed onto cart during the operation.

For the first time, the project team applied a steel plank road to the construction work featuring a super-large plane so as to resolve the problem of insufficient hoisting times of the tower crane in the middle part of the deep groove area. Regarding scheming making and designing of the steel plank road, BIM technology will be used to perform scheme comparison such as detailed BIM simulation, checking and calculating of root form, support system, component selection, and stress imposed onto cart during the operation.

vi. Steel Structure Scheme Simulation

It can establish a spatial Building Information Modeling (BIM), carry out milestone modeling and finite element calculation, calculate the deformation of the entire structure and simulate the construction process.

It can establish a spatial Building Information Modeling (BIM), carry out milestone modeling and finite element calculation, calculate the deformation of the entire structure and simulate the construction process.

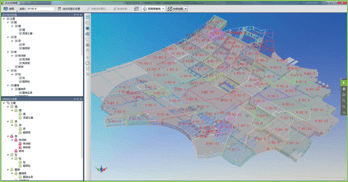

vii. Management of Streamlined Section

Based on BIM It can perform lean management for on-site construction accomplishment and completion of components through the streamlined section management based on Building Information Modeling (BIM).

Based on BIM It can perform lean management for on-site construction accomplishment and completion of components through the streamlined section management based on Building Information Modeling (BIM).

viii. Material Extraction Based on BIM

It can import the model directly into the BIM5D platform. Afterward, the software will automatically generate a material plan demand table for civil engineering and electromechanical specialty according to the options selected by the operator and submit it to the material purchasing department for procurement.

It can import the model directly into the BIM5D platform. Afterward, the software will automatically generate a material plan demand table for civil engineering and electromechanical specialty according to the options selected by the operator and submit it to the material purchasing department for procurement.

ix. Analysis of Schedule & Capital Resource Curve

By associating the Building Information Modeling (BIM) with the schedule plan, it can visually grasp the progress of the project. Furthermore, it can also use BIM software to analyze the curve of project funds and resources so as to fulfill lean management toward the construction progress.

By associating the Building Information Modeling (BIM) with the schedule plan, it can visually grasp the progress of the project. Furthermore, it can also use BIM software to analyze the curve of project funds and resources so as to fulfill lean management toward the construction progress.

x. Special Application of Pile Foundation

The team monitored the progress of every section, pile, and working procedure of pile foundation construction. and carries out multi-dimensional analysis through the data platform. Through the mobile platform, the team can immediately release the progress of pile foundation construction and the construction deviation inspection results. What’s more, the unit responsible for deviations can be notified instantly. And the plan can be compared with the actual execution, as well as the completion of the working procedure, so as to promote management efficiency and record accuracy.

The team monitored the progress of every section, pile, and working procedure of pile foundation construction. and carries out multi-dimensional analysis through the data platform. Through the mobile platform, the team can immediately release the progress of pile foundation construction and the construction deviation inspection results. What’s more, the unit responsible for deviations can be notified instantly. And the plan can be compared with the actual execution, as well as the completion of the working procedure, so as to promote management efficiency and record accuracy.