Jun 21.2023

Shaping a Sustainable Future with Digital Buildings

By Cristina Savian

The Environmental, Social, and Governance

(ESG) criteria have become increasingly important in today’s rapidly evolving

world. With companies becoming increasingly aware of their need to create a

more sustainable future, digital building is becoming increasingly clear that

it has the potential to help towards these goals as well. How do we leverage digital

buildings to promote environmental, social, and governance issues and transform them

into effective tools to create a sustainable future?

Digital Building: An Overview

A digital building refers to the

application of digital technologies and processes throughout the entire

lifecycle of a building project, starting from the initial design and planning

stages to the construction, operation, and maintenance stages. People often

believe the term only refers to operations and maintenance phases during a lifecycle;

however, its purpose, in fact, starts much earlier. To achieve our

sustainability objectives and make decision-making more effective, we must have

access to structured digital information about our building assets throughout

their lifecycle.

Having access to a digital replica of our

building can offer numerous benefits, including enhancing efficiency, reducing

costs, improving collaboration, enabling data-driven decision-making, promoting

sustainability, streamlining asset management, simplifying regulatory

compliance, optimising resource usage, streamlining facility management, and

enhancing the overall performance of the building and ultimately increasing

resilience throughout the entire project lifecycle, ultimately contributing to

the achievement of ESG goals.

ESG goals and climate change are closely

linked. The built environment is responsible for 79% of total carbon emissions

[1]

,

of which the sector directly controls 43%

[2]

.

To understand what these statistics mean, it is crucial to contextualise them

to determine what interventions are required and how a digital building may be

able to assist.

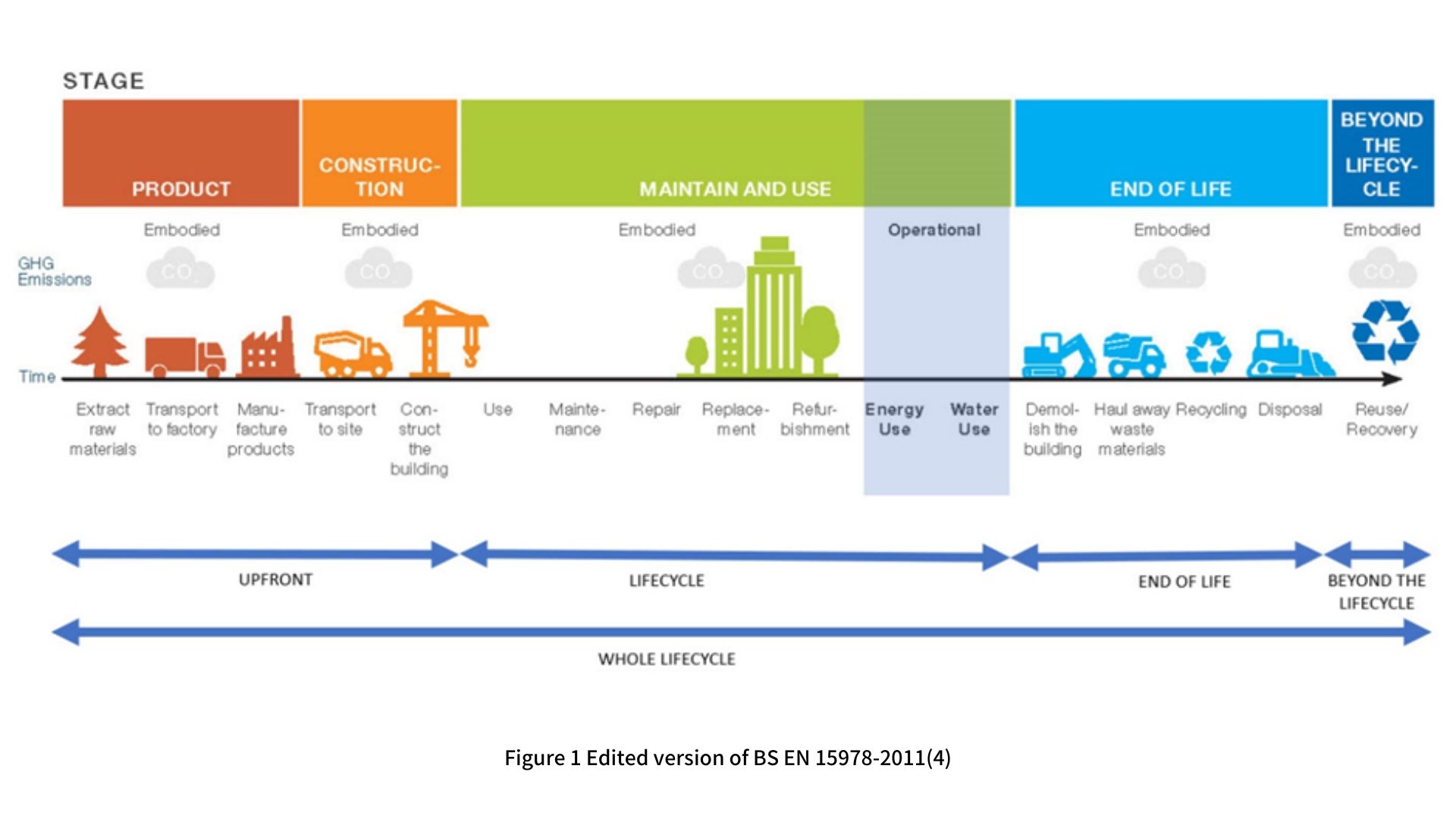

Let us first look at whole-life carbon emissions as explained by the equation provided below and illustrated in Figure 1.

Whole-life carbon emissions = Embodied

Carbon + Operational Carbon + Beyond the Lifecycle Carbon

A building’s embodied carbon emissions include the net greenhouse gas (GHG) emissions from construction materials, construction processes, and demolition throughout its life cycle. A building upfront embodied carbon is associated with construction, its lifecycle embodied carbon is associated with use, maintenance, repair, replacement, and refurbishment, and its end-of-life embodied carbon is associated with demolition, transport, and waste removal.

An asset’s operational carbon is the

GHG emissions it produces over its lifetime from energy and water use. Beyond

the lifecycle, carbon emissions are emissions beyond the system boundary

from reuse, recycling, energy recovery, and other recovery, covering aspects of

circularity.

Over the last several decades, the focus

has been on reducing operational carbon, primarily through reducing energy and

water consumption. And now, as operational carbon reduces, the importance of

embodied carbon increases.

The embodied and operational carbon

emissions of an asset or portfolio are interconnected. For instance, when

designing a building envelope, the designer should opt for one with a low

embodied and operational carbon footprint. A whole lifecycle comprehensive

approach is required in the selection process, as well as efficient data and

information sharing between project members

[3]

.

This is where digital buildings can provide assistance.

Digital Building: Impact on Reducing

Embedded Carbon

Digital buildings can significantly support

reducing the environmental impact of construction projects by minimising

embedded carbon throughout the construction lifecycle. Here are some of the aspects

that can be influenced:

Optimised Design: Digital buildings can enable architects and engineers to create more efficient and sustainable designs by allowing them to evaluate the most sustainable option. By optimising design, the types of material used and reducing waste, and incorporating energy-efficient systems, digital buildings can significantly lower the embedded carbon footprint of a project.

Material Selection:

Digital information allows in-depth analysis and comparison of different

materials based on their environmental impact. This enables the selection of

materials with lower embedded carbon, contributing to a more sustainable

construction process.

Construction Efficiency:

Digital building can streamline construction, reducing material

waste and improving resource management. This can result in lower emissions

from transportation, manufacturing, and disposal of excess materials.

Prefab and Modular Construction:

Digital building processes facilitate the use of prefabricated and

modular components, which can be produced more efficiently in controlled

environments. This reduces waste, transportation emissions, and the overall

embedded carbon of a project.

Supply Chain Management:

Digital tools can help track and manage the supply chain, ensuring

that materials are sourced responsibly and sustainably. This contributes to

reducing the overall carbon footprint of the construction process.

Adaptive Reuse:

Digital tools can facilitate the adaptive reuse of existing

buildings, reducing the need for new construction and the associated embedded

carbon emissions. By repurposing existing structures, digital buildings promote

a more sustainable and circular approach to the built environment.

Ultimately digital buildings enable a

comprehensive lifecycle assessment of building projects, considering the

environmental impact from design to demolition. This helps identify

opportunities to reduce embedded carbon during construction and throughout the

building’s operational life.

How to put digital buildings in practice

Now that we know the theory, the question

remains, how do we put it into practice? I am frequently asked about the best

technology solution for creating a digital building. While I wish there were a

single, definitive answer, the reality is that our industry is highly

fragmented, and it’s unlikely that a one-size-fits-all solution will ever

emerge. Instead, we have numerous excellent point solutions addressing specific

use cases or the challenges described above.

My best advice is to invest time and effort

in developing a well-thought-out business case that clearly identifies the

desired outcomes for the digital solution. Focus on data interoperability to

ensure that whichever solution you choose, its most valuable asset—the data—can

be easily reused and repurposed across different applications and platforms.

A platform solution approach, such as

Glodon, could indeed be beneficial. The Glodon digital building platform is

undoubtedly one of the most comprehensive and fully integrated solutions I have

encountered. However, it’s essential to recognise that the construction market

in China has evolved distinctly from the rest of the world, primarily due to

significant sociopolitical differences. The Chinese construction industry has

achieved a higher level of standardisation, supported by an exceptionally

advanced degree of digitisation. This unique development has allowed China to

establish its own construction approach, setting it apart from other global

markets and enabling companies like Glodon to develop such advanced digital

building platform solutions.

Whether we can replicate China’s achievements and apply them to the rest of the world remains to be seen. However, we currently have the opportunity to learn from an excellent practical example of how digital buildings can support sustainability, as demonstrated by the Glodon (Xi’an) R&D Centre project.

Glodon (Xi'an) R&D Centre: A Benchmark in Digital Building Practices

The Glodon (Xi'an) R&D Centre project

stands as a remarkable example of a digital building. Spanning a total

construction area of 66,000 m², the building features 3 underground floors and

12 above-ground floors. As a property owned by Glodon, the Digital Building

paradigm is employed throughout the entire lifecycle of the project,

establishing it as an exceptional benchmark for Digital Building practices.

Construction on the project began in

September 2019, and the structure was completed in May 2021. By leveraging

Building Information Modelling and Integrated Project Delivery, the project

successfully breaks through industry silos, fostering effective communication

and collaboration among all stakeholders throughout the entire lifecycle.

This innovative approach has led to

outstanding sustainability results and a significant reduction in resource

usage. Key achievements include:

·

7% faster completion compared

to traditional construction methods

·

5% fewer management personnel

required

·

0% reconstruction, eliminating

waste and inefficiencies

·

70% improvement in

collaboration compared to analogue processes

·

400,000 USD saved through

optimised construction from the initial design

These accomplishments showcase the enhanced

sustainability and resource efficiency made possible by adopting the digital

building approach.

Realistic Achievements in Digital

Building

The achievements of the Glodon (Xi’an)

R&D Centre project may not appear as remarkable as they truly are. The

results seem humbled and realistic to me, more so than the unattainable

promises made by some solution providers that no one seems to ever be able to

replicate.

This raises an important question: How many

technology solution providers construct their own buildings using their own

solutions? The answer is none, leading to another simple yet crucial question:

Why aren’t they?

By constructing its own R&D Centre,

Glodon has effectively demonstrated the practical application of its digital

building platform, thereby validating its efficacy and offering a valuable

model for the industry. This approach underscores the significance of setting

realistic expectations and attainable objectives when it comes to digital

building technology and its potential influence on the construction sector. As

a renowned quote states:

"A leader knows the way, goes the way,

and shows the way."

In my opinion, Glodon's initiative serves as a prime example of true leadership in the field, motivating others to adopt similar practices and work towards a more sustainable and efficient future in the construction industry.

[1]

Thacker S, Adshead D, Fantini C, Palmer R,

Ghosal R, Adeoti T, Morgan G, Stratton-Short S. 2021. Infrastructure for

climate action. UNOPS, Copenhagen, Denmark.

[2] United Nations Environment Programme (2022). 2022 Global Status Report for Buildings and Construction: Towards a Zero‑emission, Efficient and Resilient Buildings and Construction Sector. Nairobi.

[3] https://www.pbctoday.co.uk/news/featured/digital-twins-decarbonise-the-built-environment/124030/