Chongqing Xiantao International Big Data Valley Phase III Lot 1

Chongqing, China

-

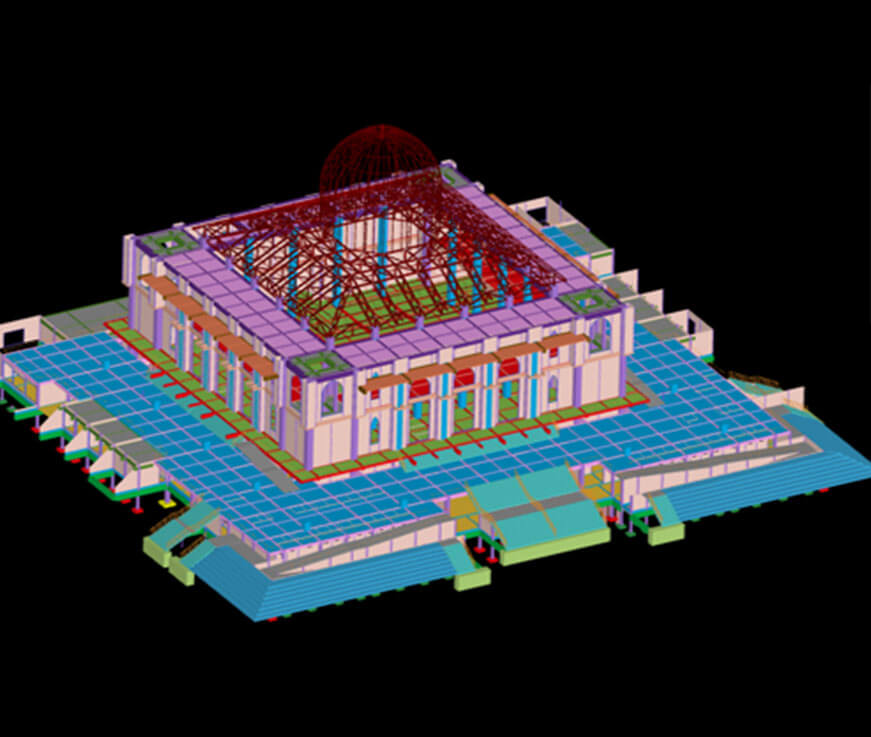

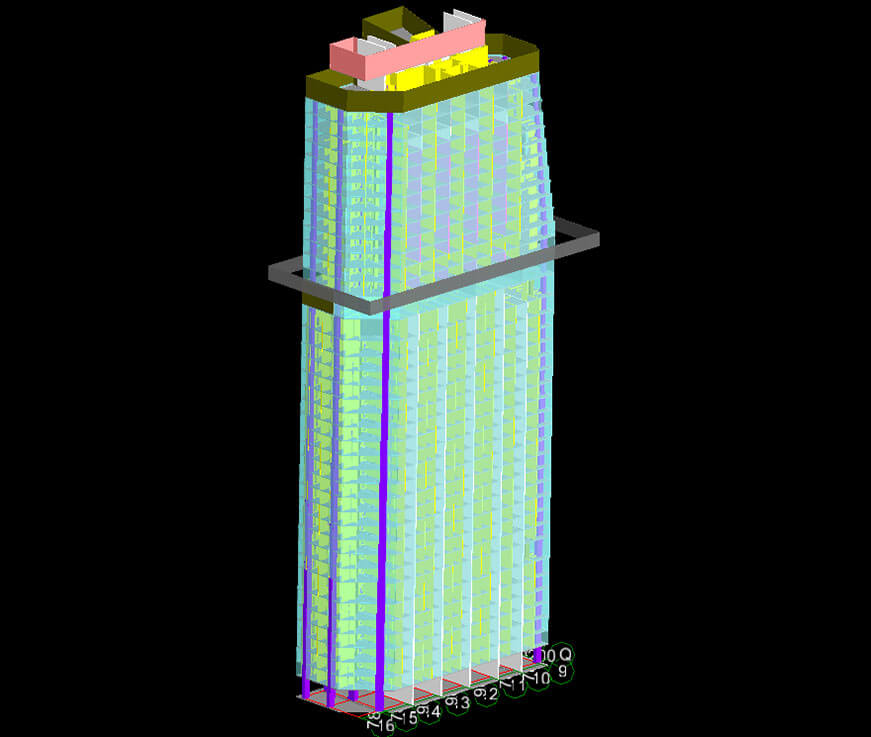

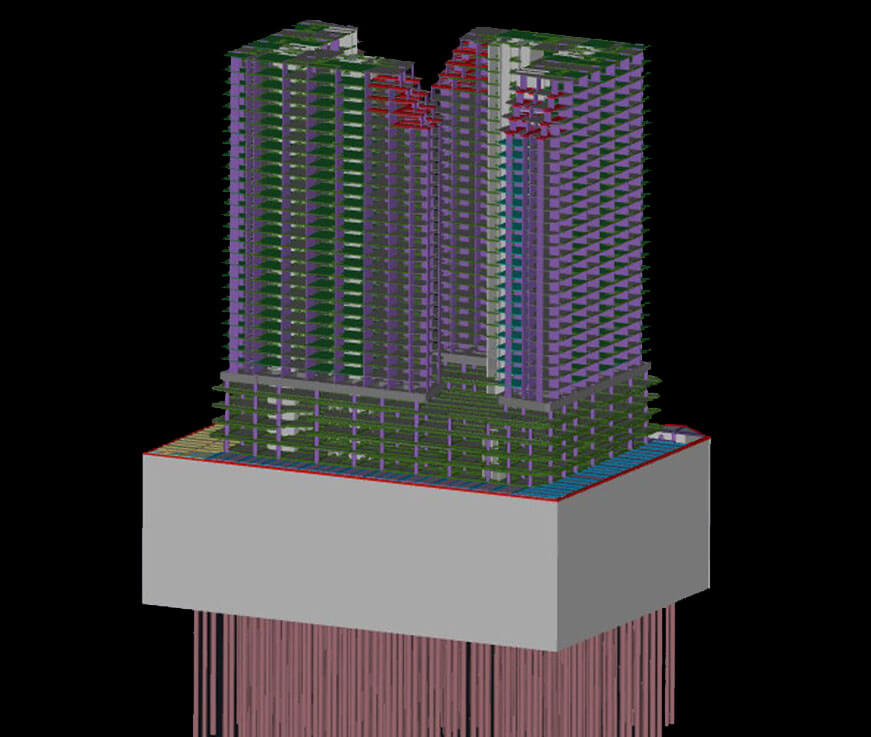

Project Type & Description: Big Data Valley, 28 units, including SOHO, villa, office garage, storage room, warehouse, tool room, etc.

-

Gross Floor Area: 300,000m², (210,000m² aboveground and 90,000m² underground)

-

Total Construction Period: 607 days

-

Main Contractor: China Construction Seventh Engineering Division Corp Ltd, Southwest Branch. (CSCEC 7th Division)

-

Glodon Products Involved: Gsite, ZPlan

ZPlan Software Shapes Better Schedule Arrangement and Project Performance

The project adopts a combination of activity-on-arrow and bar chart schedule to manage its progress. It has won 2 QC (Quality Control) achievements and 3 patents from the Engineering Bureau, published 5 excellent papers, and won awards such as the Highest Honor Award for Construction Engineering Quality in Chongqing.

The project adopts a combination of activity-on-arrow and bar chart schedule to manage its progress. It has won 2 QC (Quality Control) achievements and 3 patents from the Engineering Bureau, published 5 excellent papers, and won awards such as the Highest Honor Award for Construction Engineering Quality in Chongqing.

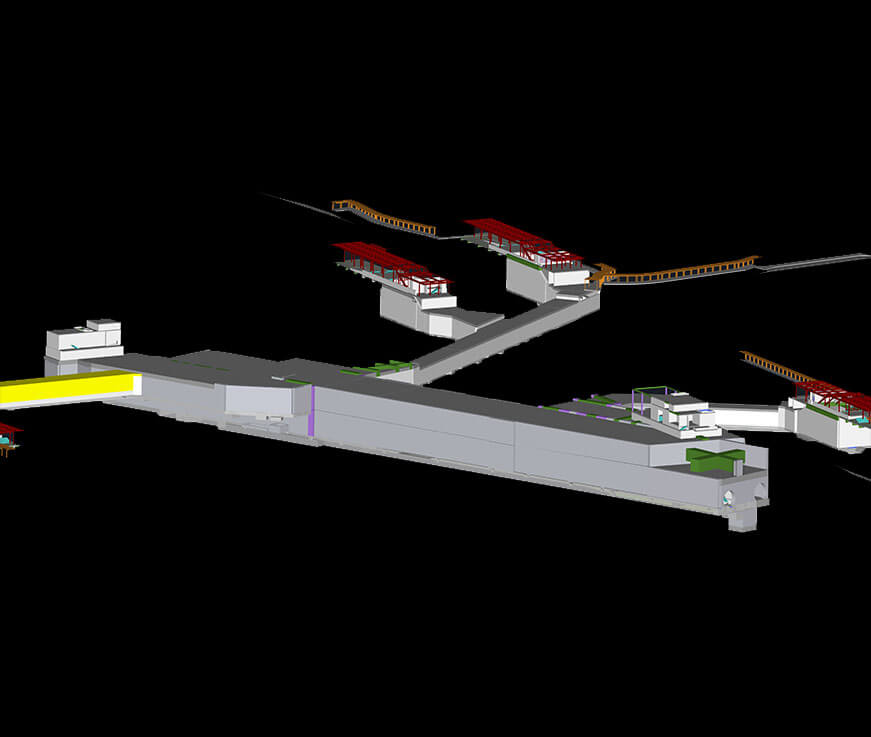

Chongqing Xiantao International Big Data Valley Phase III Lot 1 is located in Yubei District, Chongqing, and is a project integrating three functional zones which are SOHO (Small office(and) Home office), villa, and office building (including office garage, storage room, warehouse, tool room, etc.). The project covers an area of about 105,421m². The gross floor area is about 300,000m², including 210,000m² aboveground and 90,000m² underground. The main contractor is the Southwest Company of CSCEC 7th Division.

Chongqing Xiantao International Big Data Valley Phase III Lot 1 is located in Yubei District, Chongqing, and is a project integrating three functional zones which are SOHO (Small office(and) Home office), villa, and office building (including office garage, storage room, warehouse, tool room, etc.). The project covers an area of about 105,421m². The gross floor area is about 300,000m², including 210,000m² aboveground and 90,000m² underground. The main contractor is the Southwest Company of CSCEC 7th Division.

i. Challenges

This Project Has Firm & Strict Schedule & Cost Management Requirements

The project is composed of up to 28 building units that shall be constructed simultaneously. These units include twelve villas, seven multi-story buildings, eight high-rise buildings, and a unique kindergarten. The number of floors varies from 3 to 22. Thus, it is difficult to compile the schedule and supervise field progress.

This Project Is Large-Scale, with Intricate & Complicated Working Procedures

The project shall be completed after refined decoration and be fully furnished. However, it is large-scale involving quite complicated procedures; therefore, inconsistencies might occur if planning the overall schedule with traditional approaches (only preparing the overall schedule, monthly and weekly schedules).

It Is Difficult to Connect the Construction & Design Phases

This project emerged multiple stakeholders when the design and construction phase are implemented concurrently, which has increased the complexity and difficulty of managing uncertainties.

ii. Project Schedule Management Methods

At the very beginning, this project adopted the traditional management method, preparing only the overall schedule, monthly and weekly schedules. However, the project manager found this method cannot guarantee accurate and timely prediction. When dealing with uncertainties and changes, they rely more on their past site management experience. Accordingly, they established a team to address this issue and came to our ZPlan Software. They used ZPlan to prepare an AoA(activity-on-arrow) to improve the field progress management ability effectively, and also used forward line to collect the deviation between actual situations on the construction site and the plan, conducted analysis, warning, and deviation correction in time, therefore, their new plan can effectively guide the filed construction and deal with uncertainties.

At the very beginning, this project adopted the traditional management method, preparing only the overall schedule, monthly and weekly schedules. However, the project manager found this method cannot guarantee accurate and timely prediction. When dealing with uncertainties and changes, they rely more on their past site management experience. Accordingly, they established a team to address this issue and came to our ZPlan Software. They used ZPlan to prepare an AoA(activity-on-arrow) to improve the field progress management ability effectively, and also used forward line to collect the deviation between actual situations on the construction site and the plan, conducted analysis, warning, and deviation correction in time, therefore, their new plan can effectively guide the filed construction and deal with uncertainties.

iii. How They Used ZPlan to Improve Project Performance?

Change No.1 Prepare the General Control Network Plan & Define Critical Paths

Based on rational investigation and analysis, and in combination with the Gantt chart (a kind of bar chart) of the original schedule of the project, the project manager used the ZPlan Software to prepare the final network plan for each unit. There are many project units and the structures of 1#-12#, 13#-16#, 17-19#, 20#-25#, 26#, and 27-28# are the same respectively. Hence, six units’ schedules are established, optimized, and adjusted according to the actual progress on site, and integrated into a final network plan. The final network plan can show key routes and key processes clearly so that the project manager can accurately spot major problems and ensure the timely completion of the whole project.

Based on rational investigation and analysis, and in combination with the Gantt chart (a kind of bar chart) of the original schedule of the project, the project manager used the ZPlan Software to prepare the final network plan for each unit. There are many project units and the structures of 1#-12#, 13#-16#, 17-19#, 20#-25#, 26#, and 27-28# are the same respectively. Hence, six units’ schedules are established, optimized, and adjusted according to the actual progress on site, and integrated into a final network plan. The final network plan can show key routes and key processes clearly so that the project manager can accurately spot major problems and ensure the timely completion of the whole project.

Change No.2 Rational Resource Allocation

ZPlan is conducive to the preparation of resource allocation. The Project Manager indicated the buffer time of each non-critical path in the network diagram, which could help them formulate the most economical resource plan, ensuring balanced and reasonable use of resources and cost reduction.

Change No.3 Spot Project Delay with the Forward Line

The project team regularly used the forward line to compare the actual progress on-site and the plan based on the overall schedule, collect the number of days delayed and ahead of schedule, analyze the reasons respectively, to make corresponding targeted crashing measures, and assist in reporting early warning at the schedule reporting meeting.

The project team regularly used the forward line to compare the actual progress on-site and the plan based on the overall schedule, collect the number of days delayed and ahead of schedule, analyze the reasons respectively, to make corresponding targeted crashing measures, and assist in reporting early warning at the schedule reporting meeting.

Change No.4 Prepare Network Plan for Fragmentary Construction Procedures

Fragmentary construction procedures on-site make it challenging to construct and complete on time. To complete the project within schedule, the project team used ZPlan Software to carry out a separate network plan based on another reasonable and efficient resource plan of the workforce, material, and machinery. This particular plan ensured the proactive resolutions on analysis and elimination of the significant risks, and thus the timely completion of the construction.

Change No.5 Prototype Room Significantly Enhances Project Effectiveness

As a result of the significant impact the prototype room has on construction, the project adopted the prototype guidance system and prepared the prototype room network plan before its construction. An optimized prototype room network plan was devised after consultation and discussion among all stakeholders, thus ensuring its on-schedule completion.

iv. Summary of Benefits

To sum up, after the project team replaced the original method with ZPlan Software, they can better supervise the project schedule and optimize project performance. The project progress was consistent, reasonably allocating resources and effectively improving production efficiency. Moreover, the team can indicate the buffer time of each non-critical path in the network diagram, which could help formulate the most economical resource allocation plan, ensuring balanced and reasonable use of resources and cost reduction. In addition, the team used the forward line to spot the delayed and advanced work tasks, helping analyze the causes and correct errors in time. They can also clearly define key routes and processes in the network diagram. And use the technical and commercial nodes included in the network diagram to coordinate the work between various departments and relevant parties, thus ensuring the on-time delivery of the project.

To sum up, after the project team replaced the original method with ZPlan Software, they can better supervise the project schedule and optimize project performance. The project progress was consistent, reasonably allocating resources and effectively improving production efficiency. Moreover, the team can indicate the buffer time of each non-critical path in the network diagram, which could help formulate the most economical resource allocation plan, ensuring balanced and reasonable use of resources and cost reduction. In addition, the team used the forward line to spot the delayed and advanced work tasks, helping analyze the causes and correct errors in time. They can also clearly define key routes and processes in the network diagram. And use the technical and commercial nodes included in the network diagram to coordinate the work between various departments and relevant parties, thus ensuring the on-time delivery of the project.