Glodon Smart Crane Guardian

Integrating high-precision sensors and AI algorithms, the system effectively prevents tower crane collision incidents and enables proactive obstacle avoidance. By combining computer vision technology with high-definition cameras, it mitigates human-factor safety risks during crane operations.

With independently developed remote control and autonomous driving technologies, the system achieves super-long-distance remote operation from the ground. Glodon’s proprietary multi-modal data perception and fusion algorithms empower the crane with autonomous environmental awareness, path planning, and active obstacle avoidance, enabling human-machine collaborative assisted operations.

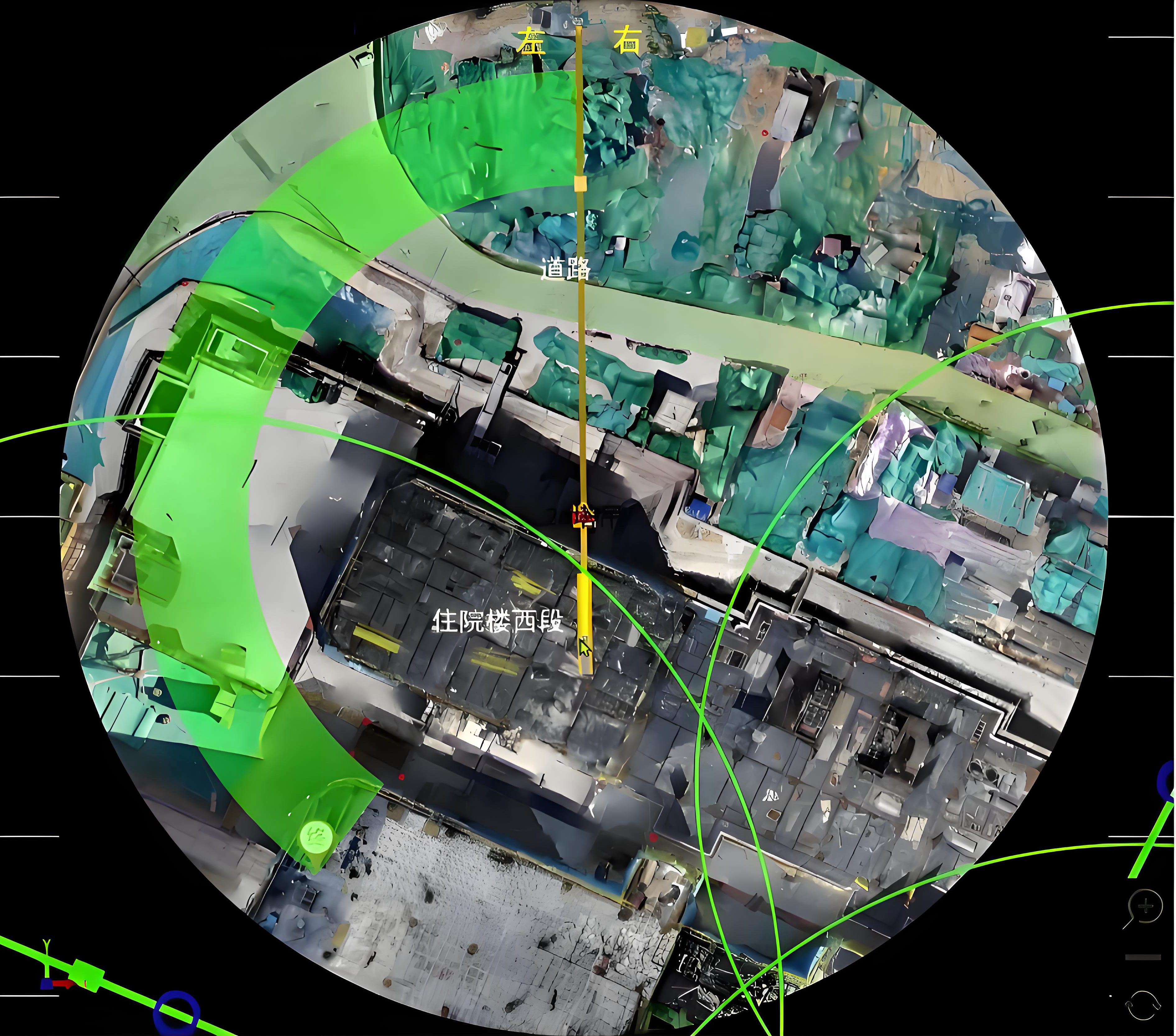

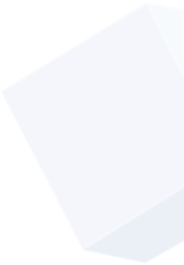

Anti-Collision for Multiple Tower Cranes

Before a crane enters an overlapping work zone, the system promptly alerts the operator, automatically downshifts and reduces speed, and—if danger persists—brakes to a stop just in time, preventing any collision.

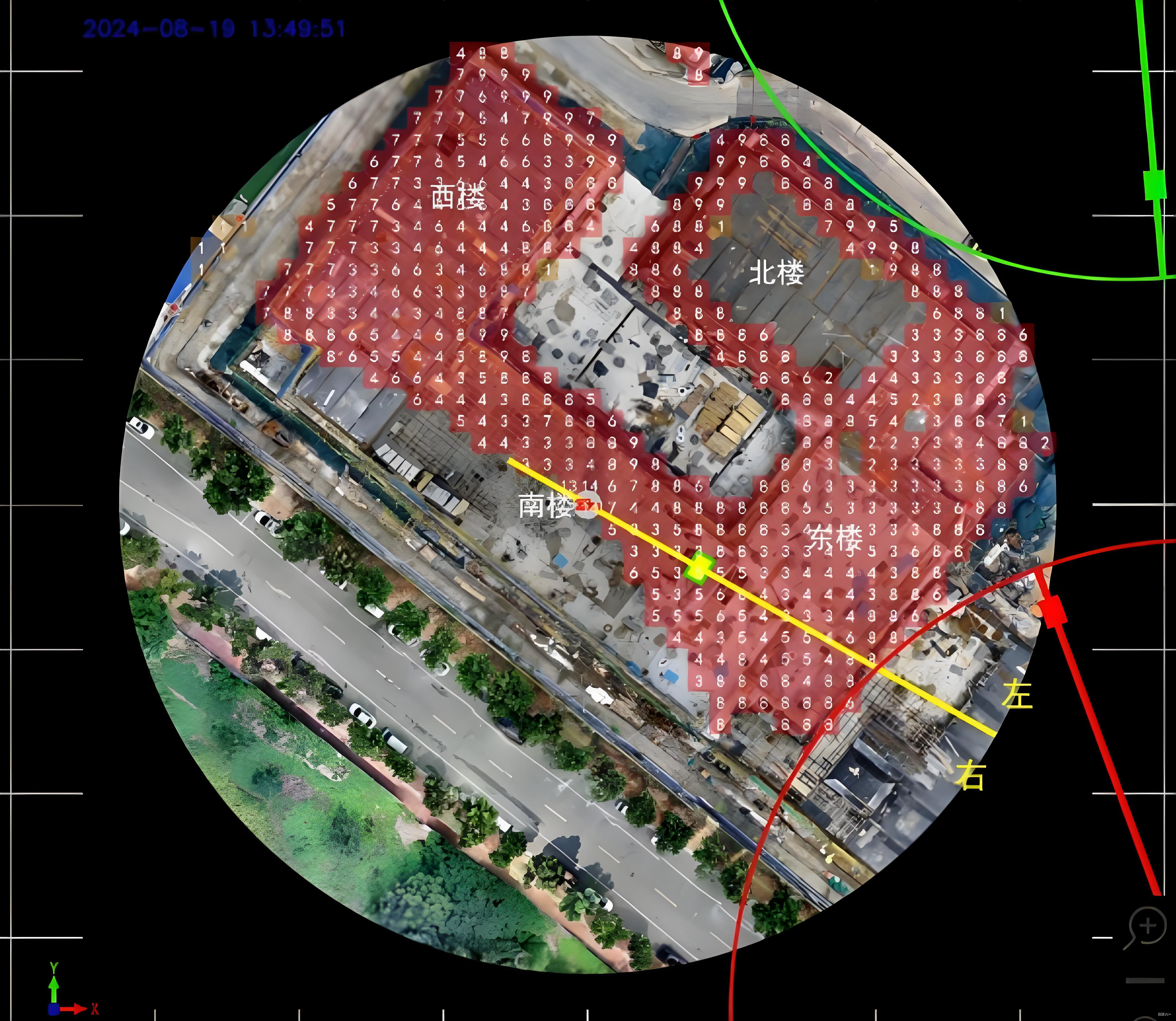

Restricted Zone Protection

The system triggers timely alerts when cranes approach restricted areas such as municipal roads, high-voltage power lines, or residential zones. It activates audible and visual alarms while proactively downshifting and reducing speed to prevent entry into hazardous zones.

AI-Based Lifting Risk Recognition

Leveraging a core algorithm that deeply integrates multi-modal data from "computer vision systems, high-precision sensors, and HD cameras," the technology accurately identifies workers, lifted loads, and the lifting hook positions.

It continuously monitors and automatically intervenes in hazardous scenarios including personnel near or on suspended loads, mixed lifting of long and short materials, and oblique lifting operations—effectively preventing such potential accidents.

Lifting Hook Visualization

The system features fully automated zoom with auto-height calibration, assisting the operator in raising and lowering operations.

This significantly reduces lifting risks in blind spots while enhancing both safety and operational efficiency throughout the hoisting process.

Safety Risk Traceability

The platform systematically records all risk alarm data during crane operations. In the event of an incident, users can retrieve corresponding risk records to review alert parameters and the reconstruct entire operation from multiple angles through trajectory playback and synchronized video footage.

Remote Piloting

Operators can monitor real-time site conditions via an intelligent dashboard at ground level while precisely controlling crane movements through a remote console.

This solution fully meets round-the-clock, all-scenario operational requirements in actual production environments, ensuring both efficiency and safety.

Obstacle Anti-Collision

Based on high-precision LiDAR, the system captures surrounding obstacles in real time. AI algorithms compute relative positions, predict collision risks, and—if a risk is detected—trigger audio-visual alarms while progressively limiting speed and braking to keep tower-crane operations safe.

Human-machine Cooperative Autopilot

By digitizing lifting tasks, intelligently scheduling them, and automating/refining crane movements, the system delivers human-machine cooperative autopilot—making tower-crane use safer, more efficient and more cost-effective.