Quality Management

a. Quality inspection: By taking photos and uploading quality problems by using mobile devices (smart phones, tablets etc.), the relevant personnel are notified to remove problems in a timely manner. Moreover, weak points of project’s quality are analysed accordingly.

b. Quality acceptance: The system covers all acceptance contents on site, including process acceptance, sample acceptance and material mobilization acceptance. The system can generate online acceptance records to track the progress of acceptance in a timely manner.

c. Actual measurement: Based on the drawings in the system, the real-time measurement and positioning are carried out via the mobile phone, various hardware including distance measuring equipment, electronic tape measure and intelligent guiding rule are connected, and the one-click transmission is carried out after data measurement, to automatically generate the multi-dimensional statistics in the system.

Technology Management

a. Technology selection: the technology can be searched based on the accumulated historical technology data of the main contractor.

b. Preparation of technical solutions includes: construction organization, and simulation and planning of solution and process (the simulation means the version shown to the developers in the bid stage, and the planning refers to the version guiding the staff to construct).

c. Collaborative management of process technical data: collaborative management of drawings, changes, solutions, and disclosures can be realized.

d. Construction disclosure to workers: visualize the construction details (eg. the plan of building a wall) with 3D Modelling Technology and simulation to better inform relevant workers before they start to build.

e. Closed-loop management: planning, teaching staff, construction, supervision and security check

Production Management

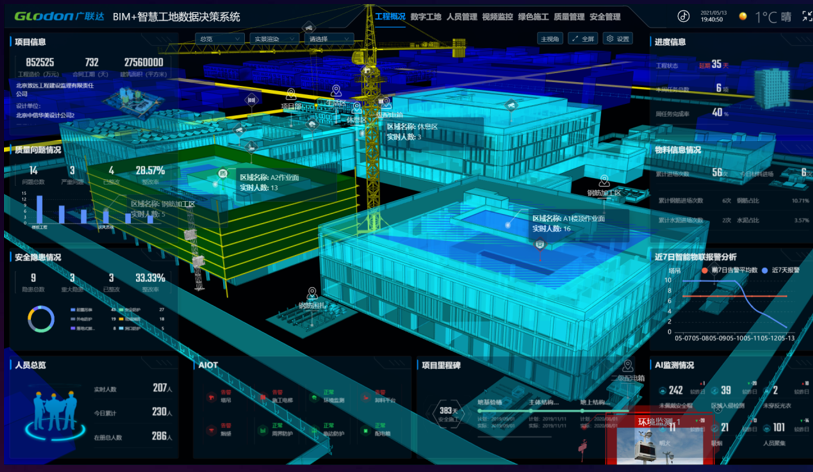

The overall progress is implemented by stages and daily production tasks. Tasks are assigned to people, the on-site progress is tracked in real time, and the planned progress is compared with the actual progress in combination with the BIM model. The system can adjust the planned progress based on the actual progress feedback. The UAV (Unmanned Aerial Vehicle) can remotely issue operation tasks and control instructions to the site. AR inspection glasses can realize three functions: face recognition, command and dispatch, and remote technical guidance.

Labour Management

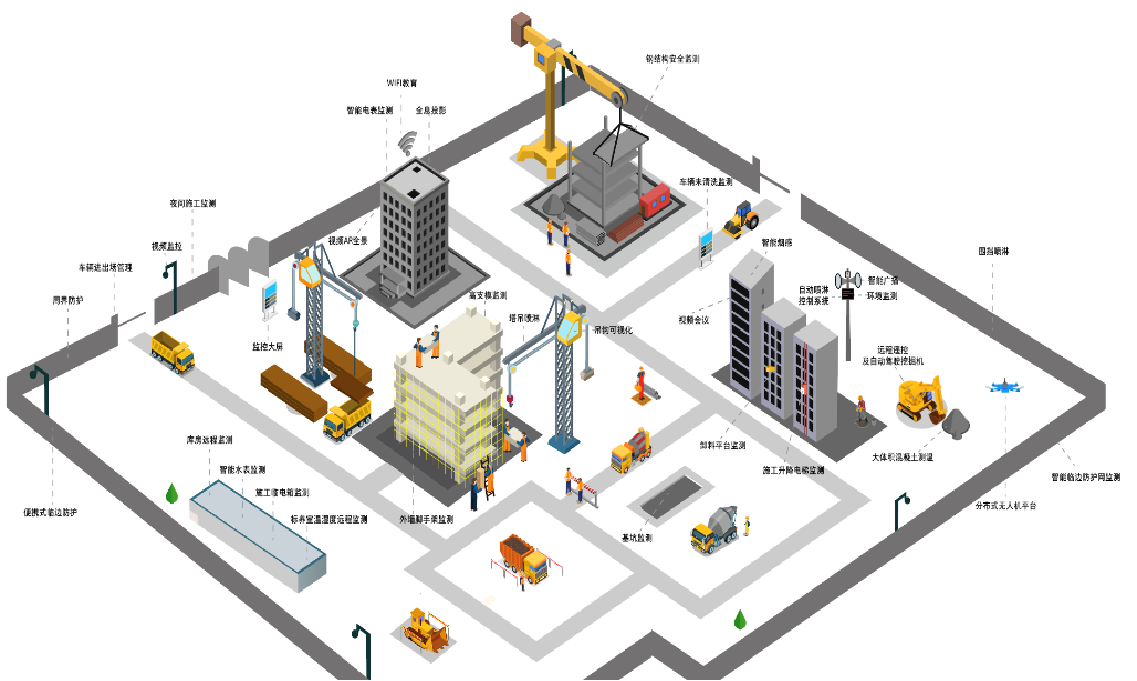

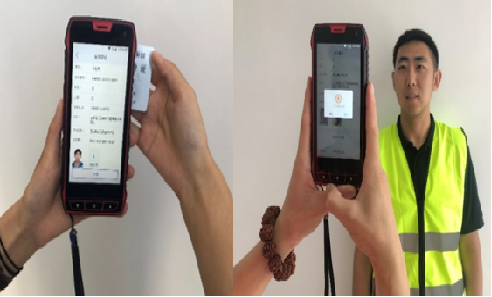

a. Before the construction: The personnel information recording and real-name registration will be quickly completed by face and ID card recognition with Sudengbao hardware equipment. The safety education box is used to complete the training and assessment of personnel before mobilization.

b. On the construction site: The gate and face recognition equipment are installed at the project site to form a green passage to complete the entry and exit of personnel without contact. The positioning technology is used for workers' safety helmets to record the personnel movement information anytime and anywhere and check the distribution of personnel and trades on site.

c. Upon completion and demobilization: The system can provide online and offline collaborative wage management, online account opening, wages paying, loan and repayment, while providing loan services for general contracting enterprises and labour service enterprises. The labour database is established to follow the employment situation in real time, regulate labour employment management, and early control of risks throughout the whole process of labour management.

Materials Management

All-round management and control are carried out for the on-site inspection and acceptance of materials, the loopholes of acceptance management are blocked, the supply deviation of suppliers is monitored, to realize the accounting of raw materials locally, thus improving the economic benefits of enterprises and project departments.

By using the IoT technology, the site is monitored through intelligent hardware to realize the automatic collection of accurate data;

By using the cloud computing technology, the first-hand data can be followed in time to effectively preserve and increase data assets;

By using the big data technology, the data monitoring of multiple projects and all-dimensional intelligent analysis can be realized;

By using the mobile Internet technology, the situation on site can be followed at all times, risks can be identified, and zero-distance intensive management and control and visual decision-making can be achieved.

HSE-compliant Construction

a. AR panorama: In addition to the traditional dome cameras and bullet cameras, AR panoramic cameras can be installed on site to provide a 180° project panoramic view.

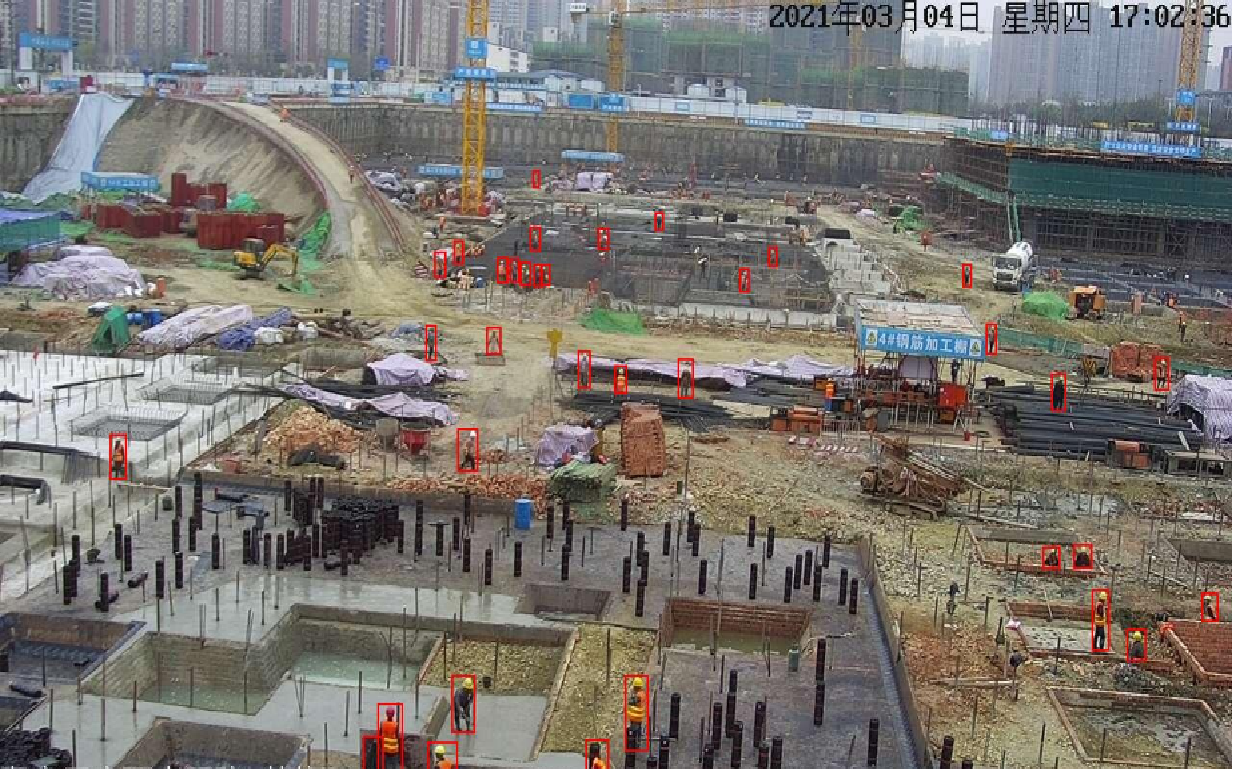

b. AI recognition: In addition to real-time monitoring of the camera itself, we have developed AI algorithms to provide high image recognition in the construction site (Smart Site platform). Therefore more than ten algorithms have been developed to capture safety hazards and personnel violations on site, such as failure to wear safety helmets, failure to wear reflective vests, open fire, smoke, mask wearing and personnel gathering.

c. Snapshot in patrol inspection: In addition to the AI algorithm, snapshot in patrol inspection, timed snapshot and automatic patrol inspection can also be set, and image progress can be automatically recorded on time every day. d. Time-lapse photography: The photos captured during the patrol inspection can be generated as time-lapse photography by setting rules in the background to display the construction process of the project in a centralized manner by visual and spatial data.

Machinery Management

The system can solve many problems from the mobilization, installation and acceptance of large-scale machinery, to the efficiency analysis of machinery and equipment in use, violation alarm and equipment demobilization.

On the BIM+Smart Site platform, combined with the tower crane model, the multi-dimensional monitoring data are displayed in real time to support the multi-directional monitoring of the tower crane operation status. Once hidden dangers are found on site, the on-site voice alarm will be given to prompt equipment operators to avoid risks. The alarm will be sent to the project management personnel through the mobile phone app, and the on-site construction personnel will be urged to make rectifications to avoid safety accidents.

By monitoring multiple tower cranes, the anti-collision inspection of a group of tower cranes can be achieved, and the torque curve of tower cranes can be automatically generated. Once the torque of a tower crane goes beyond the allowance, the alarm information will be automatically generated in the system.